Bed Cooling Technology (Patent)

Slide cooling system, effectively reducing the heat generation of the slide, reducing the coefficient of metal expansion, and reducing the temperature difference between the slide and other components. Under long-term operation, the temperature remains constant, the processing accuracy is lasting, and the processing stability is improved.

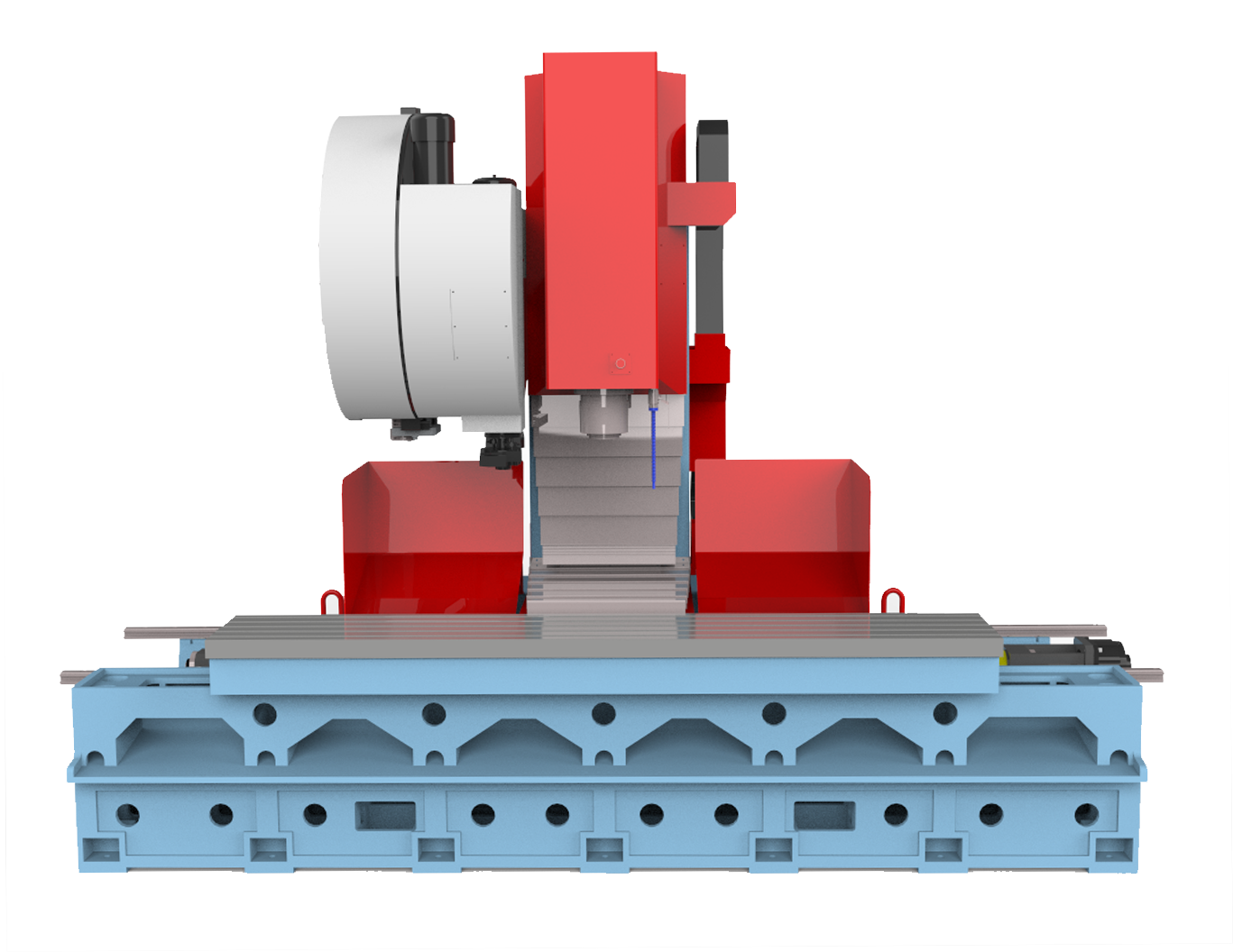

View DetailsWide Base, Four Guide Rails

The base area is larger than that of conventional models, ensuring the overall rigidity of the equipment and being more conducive to the stability of machine tool cutting. This model is equipped with X-axis configuration for the entire series, four guide rails, increasing the coverage area of the guide rails, and achieving full support of the guide rails. The column is enlarged, and the internal horizontal support rib structure more effectively enhances the column strength.

View DetailsHeavy-duty Gear Head Spindle

The headstock adopts a center water-outlet two-stage gear headstock. When the gear box speed ratio is 1:4, the torque of the servo motor is amplified four times, ensuring the large torque required for rough machining of parts. When the gear box speed ratio is 1:1, it meets the high speed required for machining fine parts or small tools.

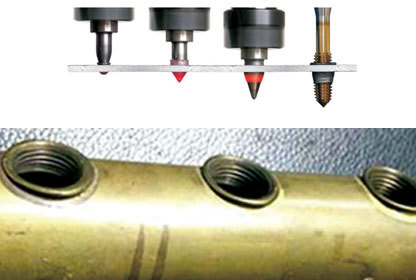

View DetailsHot melt processing technology

Using the principle that metal can be plastically deformed after high temperature, thin-walled parts are hot-melt stretched, and the whole process only takes 2-6 seconds. For processing that requires smooth connecting surfaces or chamfered holes. It can also be tapped as extrusion forming, and the processed threads can withstand higher tensile and torsional forces. The chip-free drilling and tapping process is suitable for processing ordinary steel, stainless steel, aluminum, copper, and other workpiece materials with ductility.

View DetailsRich Optional Configurations, Strong Expandability

Optional: Closed-loop control, fourth-axis rotary table, spindle central water outlet, machine tool tool setting instrument workpiece measurement, auxiliary head, tool magazine.

View DetailsHigh-strength Column, Telescopic Holes

High-strength column and telescopic holes are designed to reduce the deformation of the column due to temperature difference. This further improves stability and improves machining accuracy. Under long-term operation conditions, it effectively offsets the thermal expansion effect caused by temperature increase.

View DetailsProduct Advantages

Bed cooling (patent)

Wide Base, Four Guide Rails

Heavy-duty Gear Head Spindle

Hot melt processing technology

High-strength column, telescopic hole

Rich Optional Configurations, Strong Expandability

Cross-rib structure

The internal cross-rib structure increases the structural strength and stiffness of the casting by setting ribs inside the casting, making the casting more stable and durable when subjected to external forces. It not only improves the overall strength but also enhances its impact resistance. Improving the stress condition of the casting is also an important advantage of the cast cross-rib structure. By reasonably arranging the ribs, the static stiffness of the casting can be improved, and the deformation and damage of the casting under stress can be reduced.

Wide Base, Four Guide Rails

The base area is larger than that of conventional models, ensuring the overall rigidity of the equipment and being more conducive to the stability of machine tool cutting. This model is equipped with four guide rails on the X-axis of the entire series, increasing the coverage area of the guide rails to achieve full support of the guide rails. The column is enlarged, and the internal horizontal support rib structure more effectively enhances the column strength. The four-rail base has a larger support range, and with the ultra-rigid worktable, the height from the worktable surface to the slider surface is 275mm, and it is supported by double-layer ribs, high load, not easy to deform, and the accuracy is maintained stable for a long time.

Heavy-duty Gear Head Spindle

The head adopts a central water-outlet two-stage gear head, adopts a ¢100mm spindle, chromium-molybdenum alloy steel material, after tempering, rough and fine machining, carburizing treatment, aging treatment and precision grinding; high precision, high rigidity, and not easy to deform. After the spindle is assembled, it is calibrated by dynamic balance test. The spindle box adopts a special design of high-strength and high-rigidity cage type and keel rib structure. The spindle gear gearbox adopts gear box transmission, and the maximum speed can reach 6000 rpm (15/18.5kw), which is suitable for high-speed and heavy cutting. Two-stage switching ensures the large torque required for roughing parts and meets the high speed for finishing parts or small tools.

Hot melt processing technology

Using the principle that metal can be plastically deformed after high temperature, thin-walled parts are hot-melt stretched, and the whole process only takes 2-6 seconds. For processing that requires smooth connecting surfaces or chamfered holes. It can also be tapped as extrusion forming, and the processed threads can withstand higher tensile and torsional forces. The chip-free drilling and tapping process is suitable for processing ordinary steel, stainless steel, aluminum, copper, and other workpiece materials with ductility.

High-strength column, telescopic hole

The square box reinforced structure column is used to more effectively enhance the column strength, the internal horizontal support rib structure more effectively enhances the column strength, the high-strength column is designed with telescopic holes, and the temperature difference reduces the deformation of the column. It further improves stability and improves processing accuracy. Under the working conditions of long-term operation, it effectively offsets the thermal expansion effect caused by temperature increase.

Rich Optional Configurations, Strong Expandability

Optional full closed-loop control. Four-axis and five-axis turntables can be added to realize multi-axis linkage. Optional central water outlet of the spindle, machine tool tool setting instrument workpiece measurement, and auxiliary head. It can be equipped with a 24T disc-type tool magazine or a chain-type tool magazine with the number of tools installed.

Superior Performance

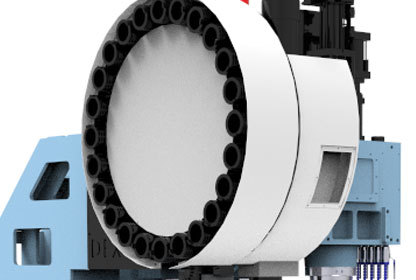

Tool change mechanism

24 tools, and adopts the latest cam-type tool change system. The tool library management adopts random memory type, which makes the tool exchange fast. After precision machining, coupled with unique heat treatment, it makes the tool change fast, reliable and accurate (no impact on the spindle) and smooth and quiet. The spindle loosening knife adopts a unique and stable gas-liquid conversion drive, which is more reliable than pure air pressure, and the floating retracting knife design ensures the rigidity and life of the spindle.

Machine tool components

All component castings use high-strength, wear-resistant alloy castings. The casting structure uses one-piece molding technology. Large components undergo high-temperature aging treatment before rough and fine machining to ensure the long-term stability of the organizational structure of large components. Our company introduces large-scale five-sided gantry machining centers and CNC gantry grinding machines from Europe as the main machines for the processing of large components to ensure the accuracy of large components.

Tool change mechanism

24 tools, and adopts the latest cam-type tool change system. The tool library management adopts random memory type, which makes the tool exchange fast. After precision machining, coupled with unique heat treatment, it makes the tool change fast, reliable and accurate (no impact on the spindle) and smooth and quiet. The spindle loosening knife adopts a unique and stable gas-liquid conversion drive, which is more reliable than pure air pressure, and the floating retracting knife design ensures the rigidity and life of the spindle.

Spindle oil-cooled constant temperature system

The spindle uses precision high-speed bearings. In addition to the use of special grease lubrication inside the bearings, the spindle is equipped with a circulating oil cooling system, so the spindle can maintain high precision under high-speed and long-time operation.

Quality service

01

Product customization

According to the customer's workpiece processing needs, customize the machine tool processing stroke, expand the multi-functional worktable, and optionally select automatic tool setting, fourth axis and other machine tool accessories.

02

Product debugging and delivery

The seller's technicians will go to the end user's factory to install and debug the equipment. The end user should notify the seller to install and debug the equipment within 5 days after the equipment arrives at the factory.

03

Product operation and technology training

On-site training at the end user's factory. The seller's technicians will go to the end user's factory to install and debug the equipment, and conduct training on machine tool operation and maintenance at the same time.

04

Perfect after-sales service

Free warranty for one year from the date of mechanical self-acceptance. However, if the damage is caused by improper use by the user unit, it is not within the above free warranty period, and the user must pay all repair costs.

Exploration and Innovation, Cooperation and Win-Win

Customer Cases

Quality Product Recommendation